In every industrial project, time and quality are central to achieving progress. The smallest component has the strength to influence the performance of an entire system. Flanges, though often seen as simple connectors, hold pipelines, machinery, and structural systems together in a dependable manner.

Suppliers of flanges contribute by maintaining a consistent flow of products and meeting the exact specifications that industries rely on.

Consistency in supply:

Industrial projects often run on strict schedules, where delays can cause significant interruptions. A flanges supplier in Dubai keeps production lines equipped by maintaining reliable stock levels and efficient distribution networks. By providing products on time, they allow industries to continue operations without interruption. This consistency builds trust between manufacturers, contractors, and suppliers, ensuring that projects advance according to planned timelines.

Meeting technical standards:

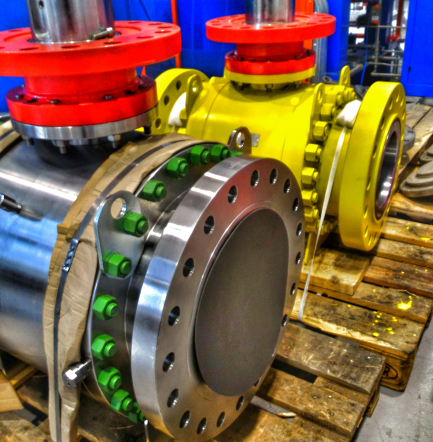

Every flange must adhere to specific standards to perform its function safely and effectively. Suppliers maintain strict compliance with international norms and testing procedures. By ensuring accuracy in dimensions, durability in materials, and proper grading, they guarantee that the flanges integrate smoothly with other components in pipelines, machinery, and structural frameworks. This reduces the risk of failure and improves the dependability of the entire system.

Supporting different industries:

Flanges are utilised in energy, construction, shipbuilding, chemical plants, and water treatment projects, among others. Suppliers understand the variations in requirements across these industries. Some demand resistance against high pressure, while others consider corrosion resistance or lighter weight. By offering a diverse selection, suppliers provide project managers with confidence that the products will match their operational conditions.

Maintaining quality assurance:

Beyond supplying products, quality assurance processes are central to supplier operations. Each flange undergoes thorough checks, such as pressure testing, ultrasonic inspection, and hardness measurements. Suppliers keep track of certifications and material traceability, so that industries receive products that align with both safety expectations and technical demands. This practice protects long-term performance and avoids costly downtime.

Allowing large-scale operations:

Large projects depend on thousands of interconnected components. Suppliers coordinate bulk orders, manage logistics, and handle export regulations where necessary. Their ability to distribute efficiently across local and international markets reduces waiting times. This reliability makes them vital partners in keeping operations running as planned.